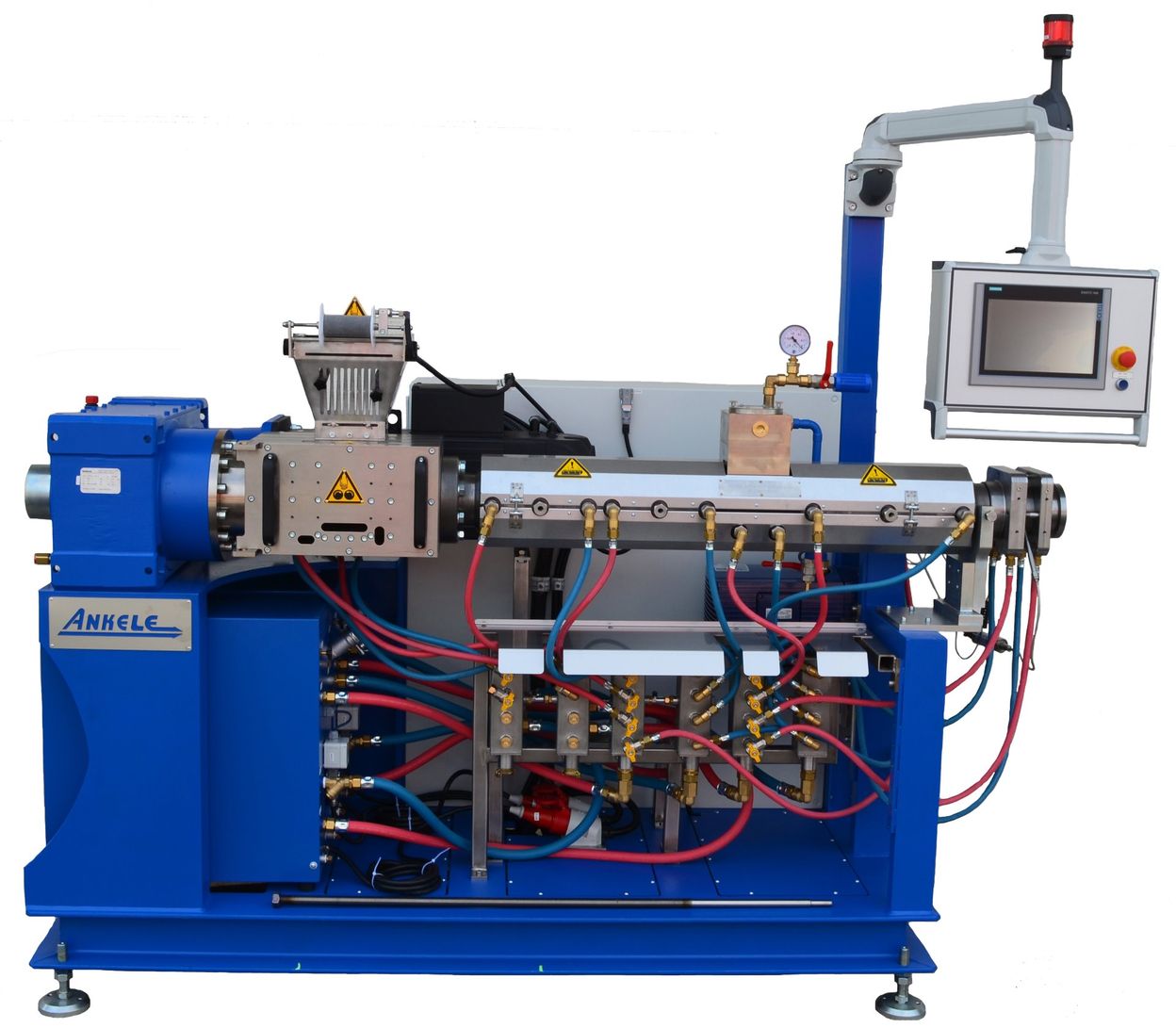

Ankele - extruder - program Ø 45 - 120

This series supplements the optimally divided series of single-screw extruders in the performance range from 40 - 700 kg/h.

Reliable mechanics

Logical: The speed and quality of your production is important to you. The combination of contemporary, state-of-the-art mechanical engineering technology with proven, simple and reliable mechanics is a guarantee of economy. The AE 1-45 – AE 1-120 series belongs to the class of compact high-performance extruders, which are also useful where tight calculations make it necessary to walk a tightrope in tough competition.

Quality is no coincidence

Ankele constructs and assembles all essential assemblies in its own production facilities. From conception to final assembly, everything is in one hand. Only aggregates and components from leading manufacturers are used - the best guarantee for a consistently high standard of quality.

Design as cylinder - screw construction

Each Ankele extruder has a screw geometry that is optimally matched to the material to be processed. Both nitrided and armored or hard metal worms are used. The material is hard-wearing and has a long service life. Due to a special design, the augers can be ejected forwards - if desired also backwards. The length of the cylinders is 25.D or 33.D with degassing. The feed area is usually smooth and nitrated. If required, the infeed can be offered with a groove.

drive and gear

Ankele extruders are equipped as standard with modern encoder-controlled AC three-phase drives. The robust, infinitely variable gear is low-noise and transfers the torque directly to the worm. A large selection of gear ratios enable the screw speeds to be optimally adjusted. Compact gear drives or gearless torque drives are also available at an additional cost.

control and process automation

Ankele builds the electronic controls for extruders and downstream systems in-house. From the central control cabinet to the fully automatic, process-controlled system, all expansion stages can be implemented. Third-party products, such as wall thickness gauges, can also be integrated into the control process. In the case of purchased hardware, only quality products from leading manufacturers are used. The control can be adapted to existing systems.

Service / Customer Service

Whether a purchase turns into a long-term partnership depends to a large extent on satisfactory support. For this reason, qualified customer service is available at short notice in the event of a fault. When you conclude a maintenance contract, we maintain and service your system on a regular basis.

Extruder

Contact

Ankele Kunststoffmaschinenbau

Inhaber Ulrich Ankele

Daimlerstraße 42

75433 Maulbronn

Copryright: Ankele Kunststoffmaschinenbau, Maulbronn