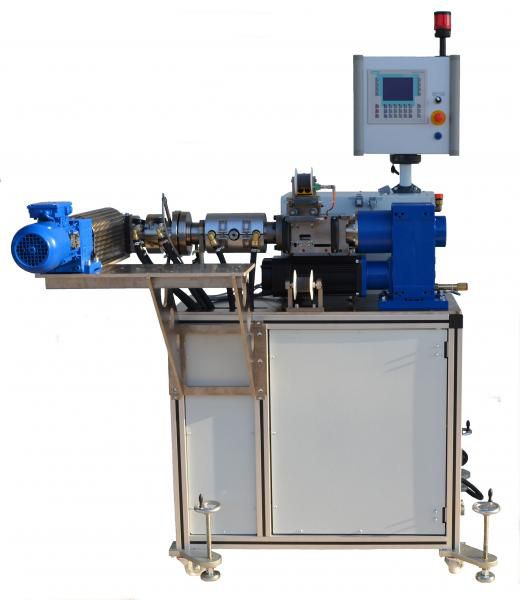

Ankele - single-screw rubber-silicon and India rubber extruders

We design and build custom laboratory and production machines for processing rubber, silicon and India rubber compositions.

The main difference regarding the Standard Ankele Thermoplastic Extruders is the use of different raw materials:

- supervised roles enemas with ribbon or strip guide

- feeder aids such as directly or separarely driven feed rolls

- Fluid-heating of cylinder, adapters and tools

By default, the machine series is equipped with its own Siemens PLC. Of course, these machines can be additional equipped with various options.

- funnel with compactor hopper for processing mixtures in granular form

- directly or separately driven feed roller blocks

- vents in the cylinder for static and / or vacuum degassing

- cylinder doser apertures

- melt pump for rubber and silicone

- special tools and adapters

- belt haule-offs for profile transport immediatelly after the nozzle

Ask in your particular case, we will advice you

Extruder

Contact

Ankele Kunststoffmaschinenbau

Inhaber Ulrich Ankele

Daimlerstraße 42

75433 Maulbronn

Copryright: Ankele Kunststoffmaschinenbau, Maulbronn